Material Innovation Is a Powerful Freedom of AM: Here Are Examples

Possibilities that were speculative a few years ago are coming true today. Applications of metal matrix composite provide an example. Recent articles explore the ongoing advance of 3D printed materials.

Part of the thrill of being witness to a disruptive and fast-moving technology category is found in the promise. Each new development of the technology invites anticipation of what the full promise of that development might be. In our coverage of additive manufacturing (AM), we give healthy attention to the promise; we voice the anticipation. But this leads to the other part of the thrill: seeing the potential realized, seeing the promise fulfilled. In the area of materials for AM, that is what we are seeing today.

In Additive Manufacturing, Materials Are Where It’s At

It was not long ago — as recently as four or five years — that I found myself repeatedly stressing what then seemed to be an underappreciated point. Namely, that the most powerful aspect of the design freedom of additive was apt to come from materials. (I stressed it here, for example.) At the time, many were just awakening to the geometric freedom: the lattices, lightweighting, conformal channels, consolidation and topology optimization. Just that much was a lot. Now, it is clearer, and more widely accepted, that the chance to make different choices in material, thanks to AM, offers even greater scope for getting to the full potential of a manufactured part. As one leader of a maker of AM equipment recently offhandedly said to me (he was referring to his own company’s aim to do better in this area), “Materials are where it’s at.”

Metal 3D Printing Goes Beyond Metal

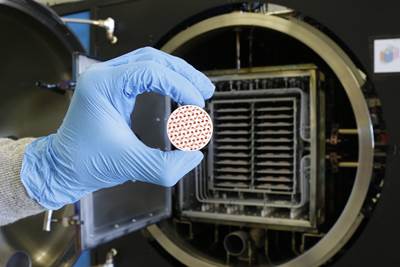

For an example of this point playing out — that is, the promise of AM materials being fulfilled — one of the clearest cases I’ve seen involves Elementum 3D. This materials engineering firm in Erie, Colorado, pioneers new metal possibilities for laser powder bed fusion (LPBF), particularly EOS’ platform. I first covered the company in 2017, when I visited the company’s facility — essentially a large workshop back then — to learn about its then-new development of a new material type for LPBF: not a metal but a metal matrix composite. That is, laser 3D printing of a mix of aluminum and ceramic (even though only the former is melted by the laser) to achieve a composite merging the light weight of one with the heat resistance of the other. Now, Elementum 3D is a bigger company in a nicer facility, and the promise has been achieved: End-use parts make full use of the aluminum/ceramic material.

Indeed, one set of these parts is being readied for the moon. Thanks to this material, NASA contractor Masten Space Systems was able to develop a lightweight, reusable, 3D printed aluminum/ceramic rocket engine able to deliver payloads to the lunar surface once NASA begins its return there.

The aluminum/ceramic brake rotor eliminates two-thirds of the weight and improves heat transfer by a factor of five. We discussed the rotor in this episode of The Cool Parts Show.

Meanwhile, another part is headed for production. Ceramic Disc Technology (CDT) has completed development of a brake rotor for performance automobiles. The aluminum/ceramic material combined with 3D printed lattice geometry delivers a brake rotor that is two-thirds lighter and five times better at conducting heat compared to the rotor it replaces. I know these parts well, Masten’s and CDT’s, because we filmed episodes of our video series The Cool Parts Show about both applications. (Here is the episode about the CDT rotor and here is the one about the rocket engine.) Of the two, the CDT part arguably represents the greater manufacturing win. The rotor fills the build area of the EOS 400 machine on which it is made, so it might be the largest serial production part yet for LPBF in metal. In short, it is a metal AM milestone for a part that is not just metal, but also something more.

Additive Manufacturing for Copper, Thermosets, Composites

And the advances in this area continue. Several recently posted articles speak to important themes in materials. Additive is becoming capable for more and more of the material possibilities used in conventional processing, including both copper and thermoset plastics. Meanwhile, AM changes the material possibilities available to established industries, notably home construction. It also enables new ideas for sourcing materials, including the chance for US supply of materials important to the Department of Defense. Plus, it promises to expand the reach of another area of manufacturing technology that is even more materials-focused: reinforced polymer composites.

Additive Manufacturing for Ceramics

And then there is this all-new method of 3D printing ceramics, which reminds me of Elementum 3D for reasons that go beyond the connection to heat resistance. The ceramics 3D printing method involves a promising idea that is still unproven, still undeveloped, still young. How far will this idea go?

We have seen stories like this play out already. So let’s keep watching to see whether the promise of this development, too, will be realized soon.

[Related: Here is much more on 3D printing of ceramics]

Related Content

NIOSH Publishes 3D Printing Safety Guide for Nonindustrial Settings

NIOSH has published a 3D printing safety guide for small businesses and other additive manufacturing users such as makerspace users, schools, libraries and small businesses.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreA Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

The Case for Tackling the Toughest Material First

The increasing speed and power of high-end processors and data centers has created a market for advanced thermal management solutions. A Silicon Valley startup called Holo is dedicating its first line of products toward this market, starting with 3D-printed copper heat exchangers.

Read MoreHow 3D Printing Will Change Composites Manufacturing

A Q&A with the editor-in-chief of CompositesWorld explores tooling, continuous fiber, hybrid processes, and the opportunities for smaller and more intricate composite parts.

Read MoreIs a Gel Bath the Key to Scalable, Affordable 3D Printed Ceramics?

3D printed polymer-derived ceramics (PDCs) could find wider application through a process developed at the University of Texas at Dallas that extrudes preceramic material in a self-healing bath for support through printing and curing.

Read More